Data driven maintenance for better decisions!

Through real-time monitoring and predictive maintenance, faults can be detected before they occur, reducing unplanned stops by up to 50% and improving machine availability. Companies see a significant increase in Overall Equipment Effectiveness, while maintenance personnel have better planning capabilities and reduced time for emergency interventions. With history and updated basic data, more accurate decisions are made, where interventions can be prioritized based on actual wear and risk.

More efficient processes produce results!

+50%

Lower maintenance costs

Through digitalization and automation of maintenance processes!

+20%

Improved access to real-time data

Leveraging real-time data and AI-based analysis improves processes!

+75%

Predictive maintenance

Fewer emergency repairs after transitioning from reactive to predictive maintenance!

Automated maintenance solution creates significant value!

Data driven decision making

Historical and sensor data provide insights for optimizing maintenance strategies. Provides the ability to prioritize interventions based on actual wear and risk.

Improved delivery precision

More stable production reduces the risk of delays to customers and provides increased customer satisfaction.

Scalability & future proofing

Automation enables expansion without increasing complexity with integration with your INFOR M3 solution, giving you a holistic view of your business.

More efficient use of resources

Maintenance personnel can plan their operations better and spend less time on emergency operations and troubleshooting!

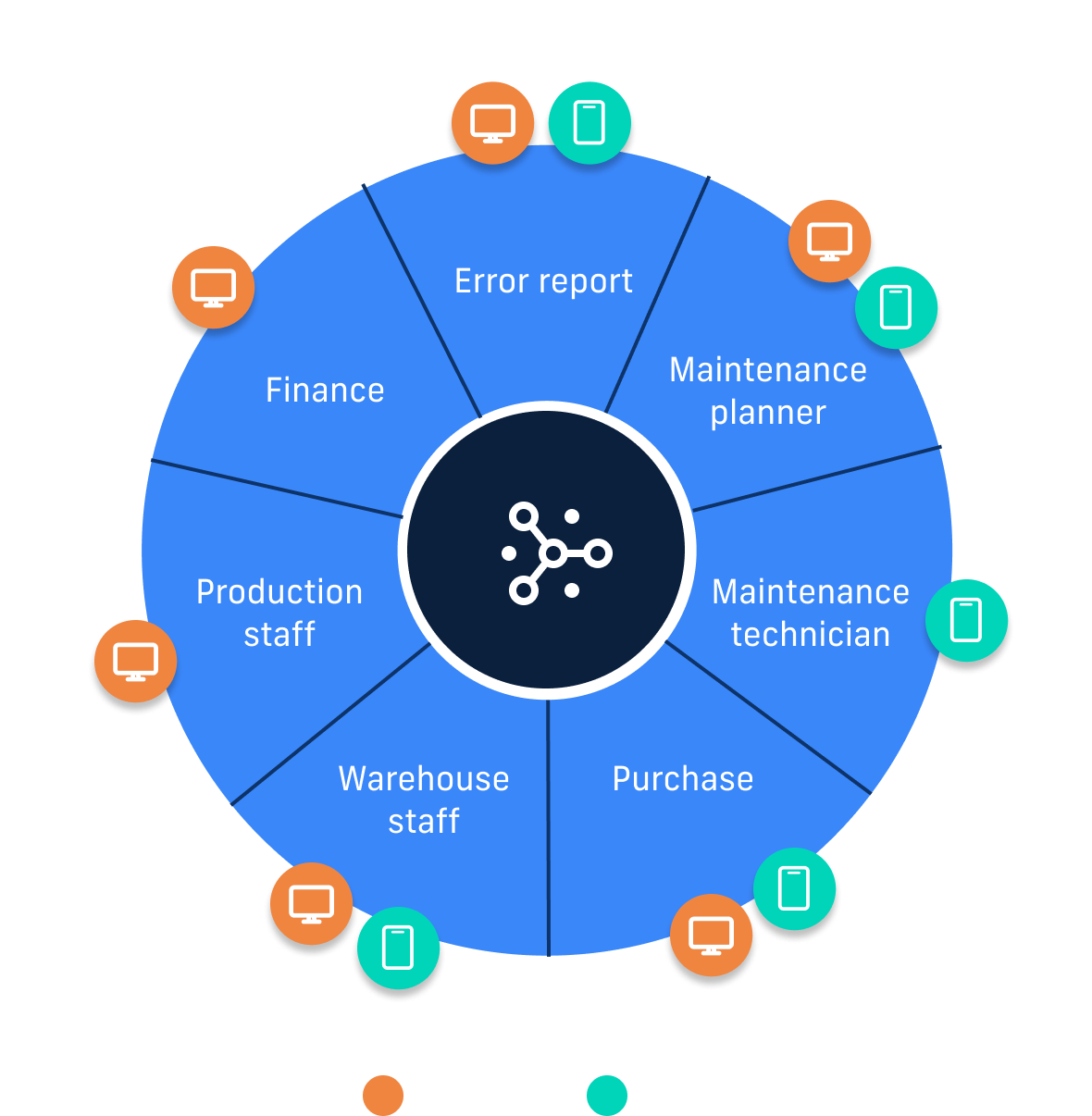

A solution for everyone involved!

With a fully integrated and process-optimized solution for error reporting, planning, feedback and follow-up, opportunities for predictive analysis are created that give you significant operational and financial effects.

There are many roles involved and everyone needs to have their own view to make each role’s work as effective as possible.

Benefits of a cohesive maintenance solution

There are many roles involved and all need their own view and work tools to do their work as efficiently as possible.

Some roles have a desktop as their primary solution, others need a mobile application solution when they are out in the field and doing physical maintenance.

Regardless of the role, it is of utmost importance that the integration between the processes runs completely frictionless and in real time.

Maintenance package for INFOR M3

A cohesive solution for all roles involved in the maintenance process!

The mobile application ProApps

Fully integrated with INFOR M3, providing complete flexibility!

The delivery project

A packaged delivery. Standard approach from the first meeting to the delivered solution!

Our mechanics work in large factory areas and historically it has always been a challenge to manage what is to be done, share information and find deviations in the plants. Digitization has enabled the introduction of mobile solutions for the maintenance system in on-line or off-line mode, depending on the location. Today, our mechanics have access to the right information and are one button away from aa deviation report. Digitization offers tools that create conditions for more efficient and secure maintenance

Daniel Keskitalo, Maintenance manager at LKAB Narvik.

If you would like to contact us, please leave your details in the form below.

If you would like to read more about each application mentioned on this page, please refer to the links below.

Business system

Business application

Smooth operations

Smooth operations

Fill in your contact details below, and we'll be in touch and tell you more.