The maintenance package delivery project

Our methodology gives you a safe delivery!

We know that maintenance projects can be complex and difficult to navigate. That’s why we offer a proven methodology for implementing Infor Cloud Suite/M3 Maintenance – with clear steps and defined goals. This means you get a safe, cost-effective and transparent journey from current state to full functionality.

This is included

Delivery

Delivery start

- A full day on site at your place

We go through the following processes

- Error reporting – Planning – Feedback

- Purchase of materials and services against work orders

- Stoppage management

- Preparation of maintenance plan

- Stock management

Then, a test environment is established where we can together validate and ensure that your M3 offers what you need now and in the future.

- Proof of Concept on selected processes

- Data adaptation for recognition

You will have three months to test the Proof of Concept, after which the solution will go into live production.

Deliverables

The project

- Process map Navcite maintenance

- Basic package according to IPC (standard processes):

- Maintenance processes (maintenance standard at the bottom)

- Purchasing processes

- Warehouse processes

- Plant processes

- Financial processes

Optional

- Digital management of work access / work permits

- Error codes & error code analysis

- Criticality classification of objects

- Integrations with equipment / objects, MES

- Additional BI reports for monitoring KPIs

Migration

- Data for loading objects and plant structure

- Data for loading maintenance programs

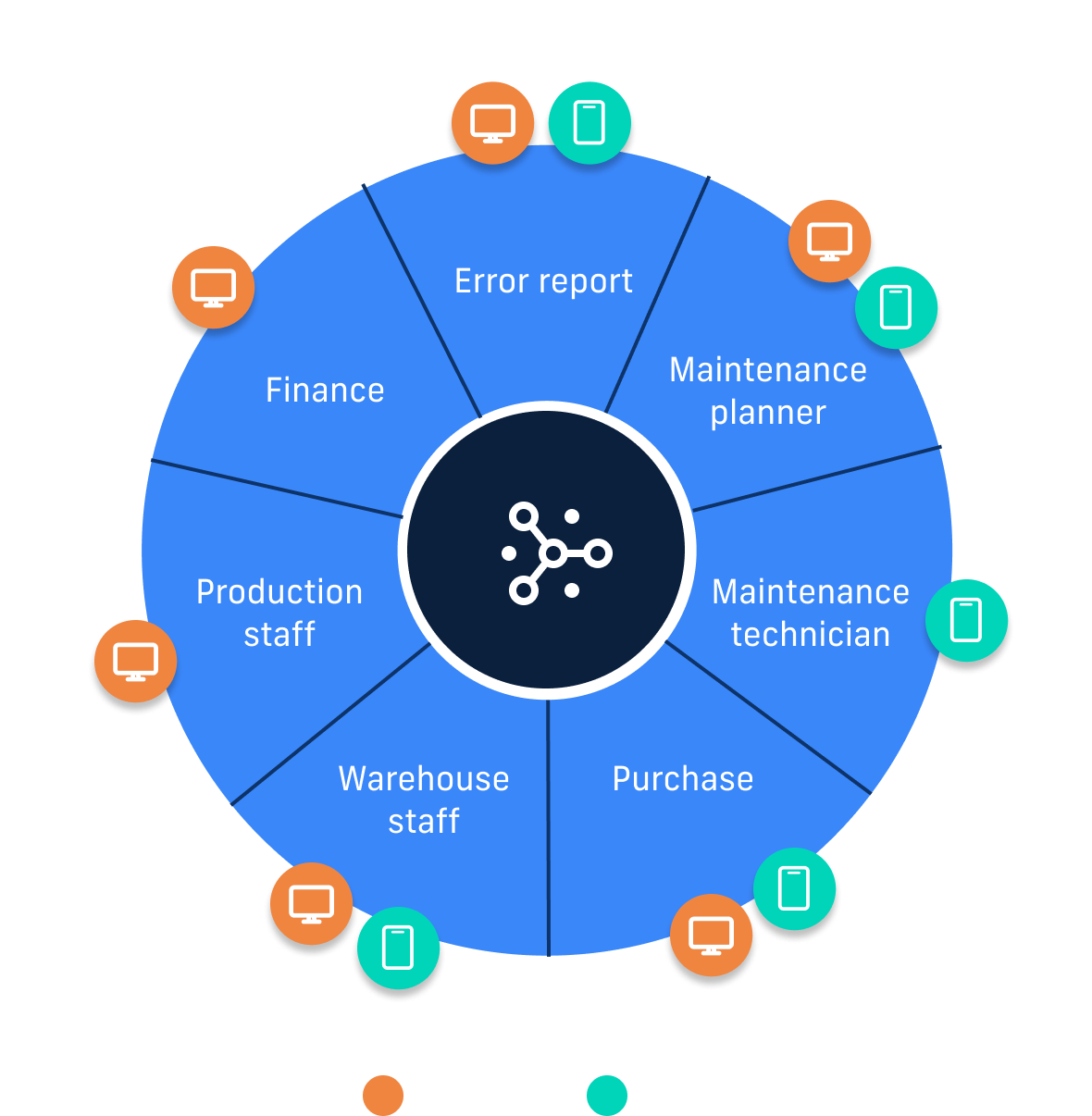

A solution for everyone involved!

With a fully integrated and process-optimized solution for error reporting, planning, feedback and follow-up, opportunities for predictive analysis are created that give you significant operational and financial effects.

There are many roles involved and everyone needs to have their own view to make each role’s work as effective as possible.

Benefits of a cohesive maintenance solution

There are many roles involved and all need their own view and work tools to do their work as efficiently as possible.

Some roles have a desktop as their primary solution, others need a mobile application solution when they are out in the field and doing physical maintenance.

Regardless of the role, it is of utmost importance that the integration between the processes runs completely frictionless and in real time.

Maintenance package for INFOR M3

A cohesive solution for all roles involved in the maintenance process!

The mobile application ProApps

Fully integrated with INFOR M3, providing complete flexibility!

The delivery project

A packaged delivery. Standard approach from the first meeting to the delivered solution!

Our mechanics work in large factory areas and historically it has always been a challenge to manage what is to be done, share information and find deviations in the plants. Digitization has enabled the introduction of mobile solutions for the maintenance system in on-line or off-line mode, depending on the location. Today, our mechanics have access to the right information and are one button away from aa deviation report. Digitization offers tools that create conditions for more efficient and secure maintenance.

Daniel Keskitalo, Maintenance manager at LKAB Narvik.

If you would like to contact us, please leave your details in the form below.

If you would like to read more about each application mentioned on this page, please refer to the links below.

Business system

Business application

Smooth operations

Smooth operations

Fill in your contact details below, and we'll be in touch and tell you more.